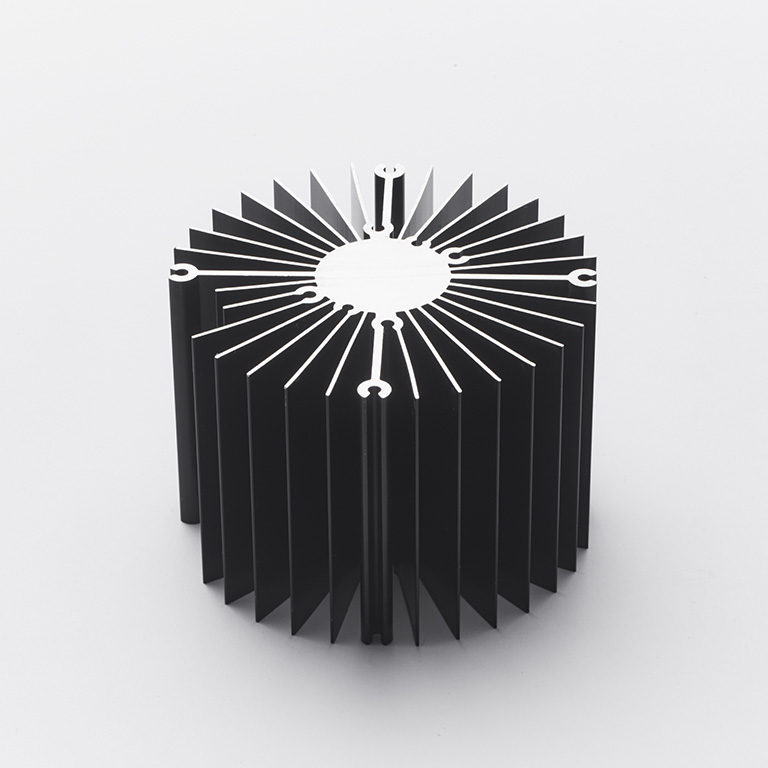

From casting to aluminium profiles.Custom technical products and prototypes

We specialise in the development and production of high-quality cast parts, plastic parts, aluminium profiles, prototypes and components. Why? Because we are true experts with extensive experience in these product areas. And because we can supply you with the perfect solution for your needs as a result. Our products are made according to our specifications by manufacturers as experienced as we are – with uncompromising quality and in any lot size (if needed also in small quantities). We will support you from the development of an idea and the production of a prototype to series production. All parts will be supplied with the desired surface treatment: galvanic chrome, nickel, gold and/or wet-coated or powder-coated.

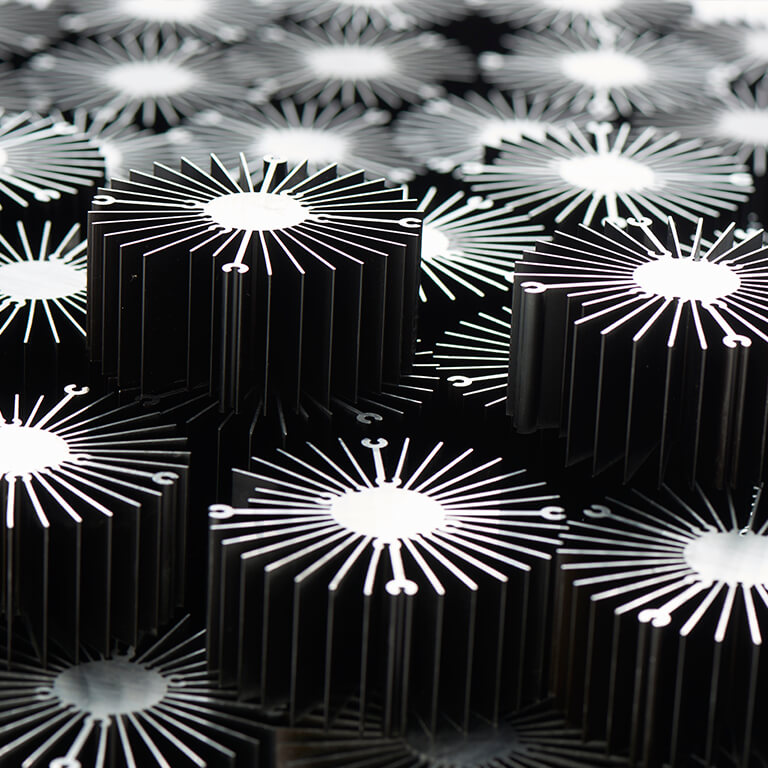

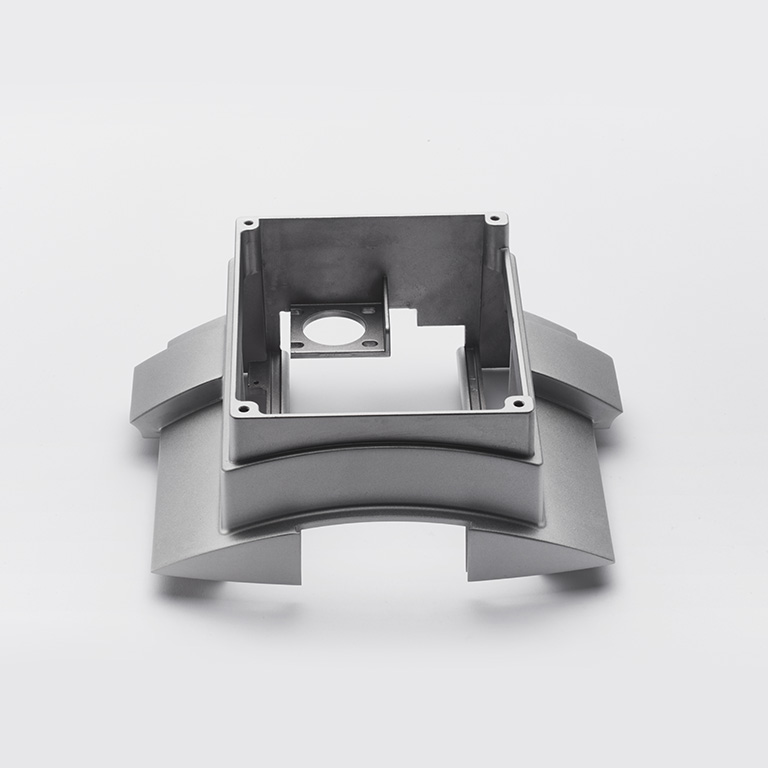

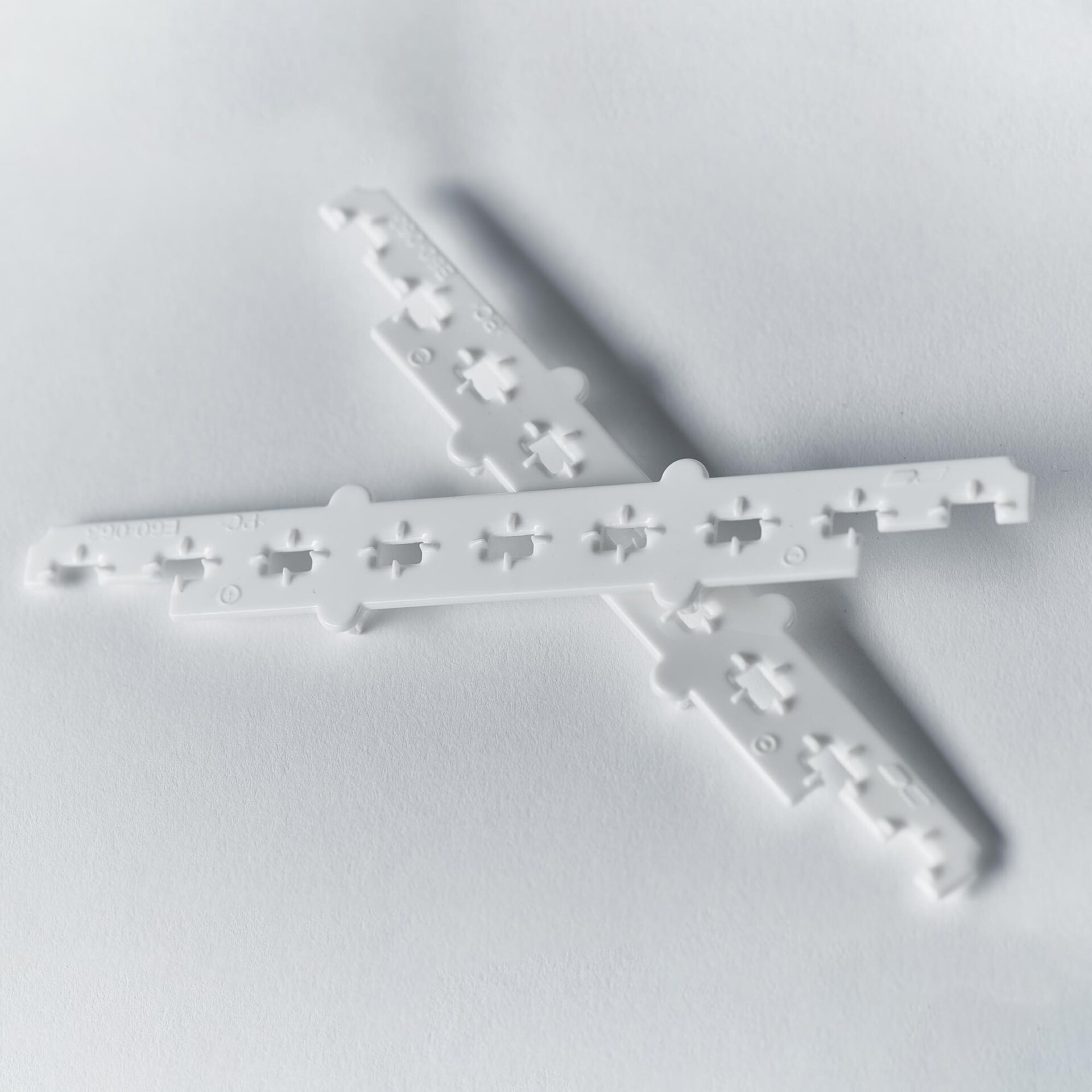

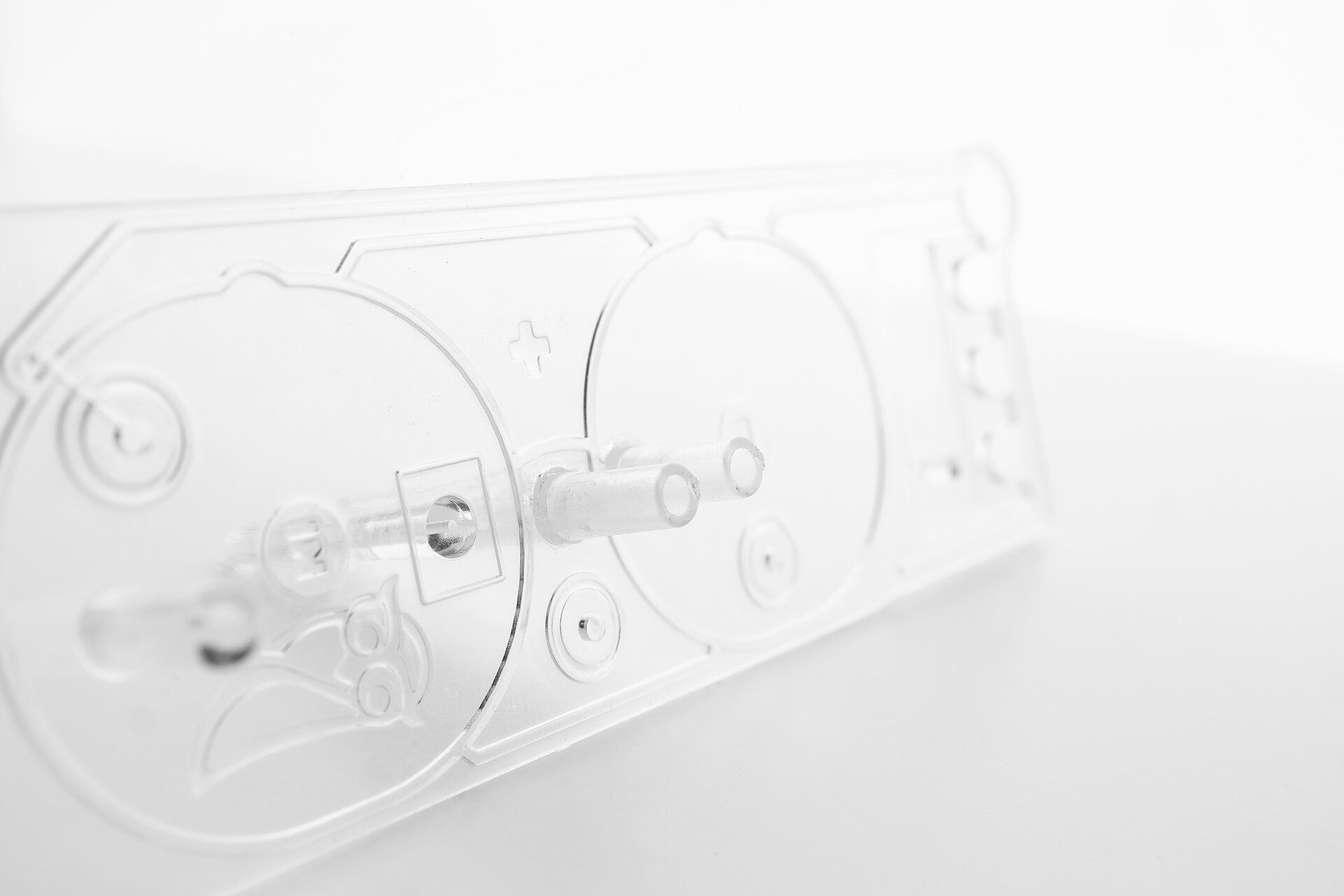

PLASTIC PARTS

Flexibility is our greatest strength in the plastic parts segment – especially in small and medium lot sizes. True to the motto: "There is no such thing as 'we can't do that'." That is why we are using a wide range of raw materials and finished products to manufacture plastic parts, which also allows us to complete short-term projects. The injection-moulded parts made from high-tech plastics and technical thermoplastics are used, among others, in mechanical engineering, the lighting industry and the sanitary sector.

We are also offering decorative plastic metallisation through vacuum coating. That allows us to give copper, aluminium, tin, gold or silver coatings different metallic effects, such as a stainless steel, aluminium, old brass or gold effects – and even colourful top coats are possible.

WE USE THE FOLLOWING RAW MATERIALS TO PRODUCE PLASTIC PARTS:

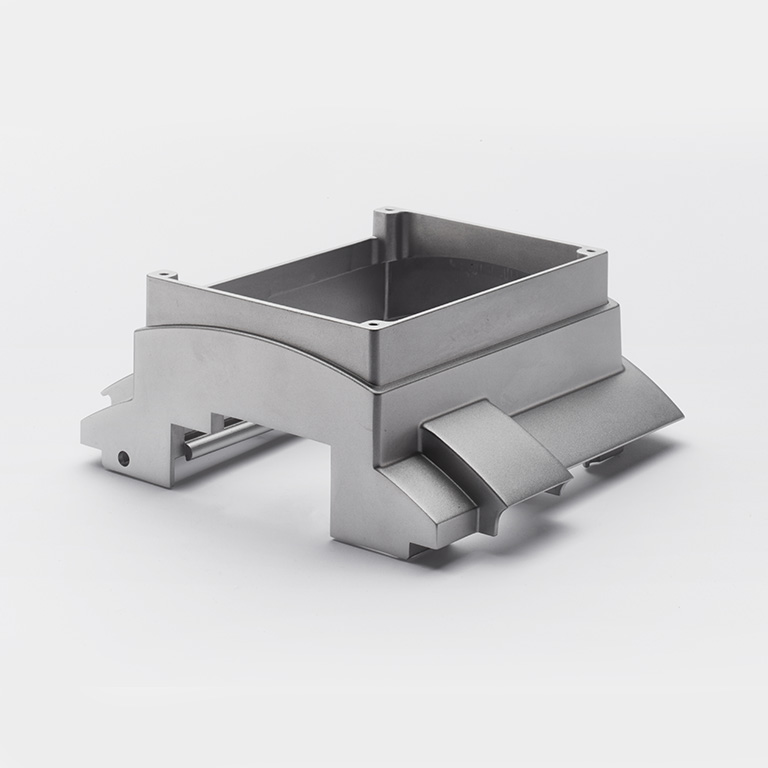

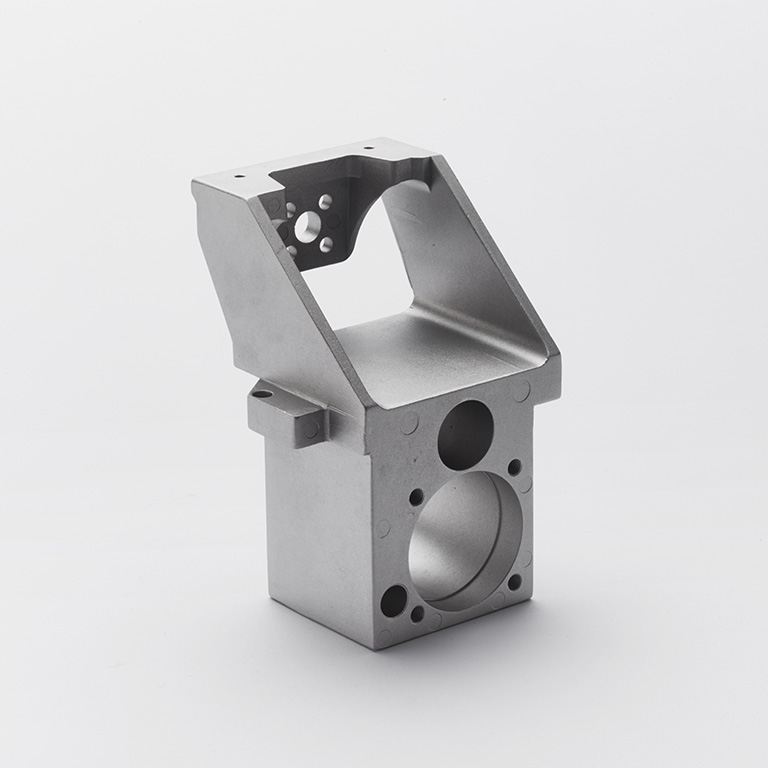

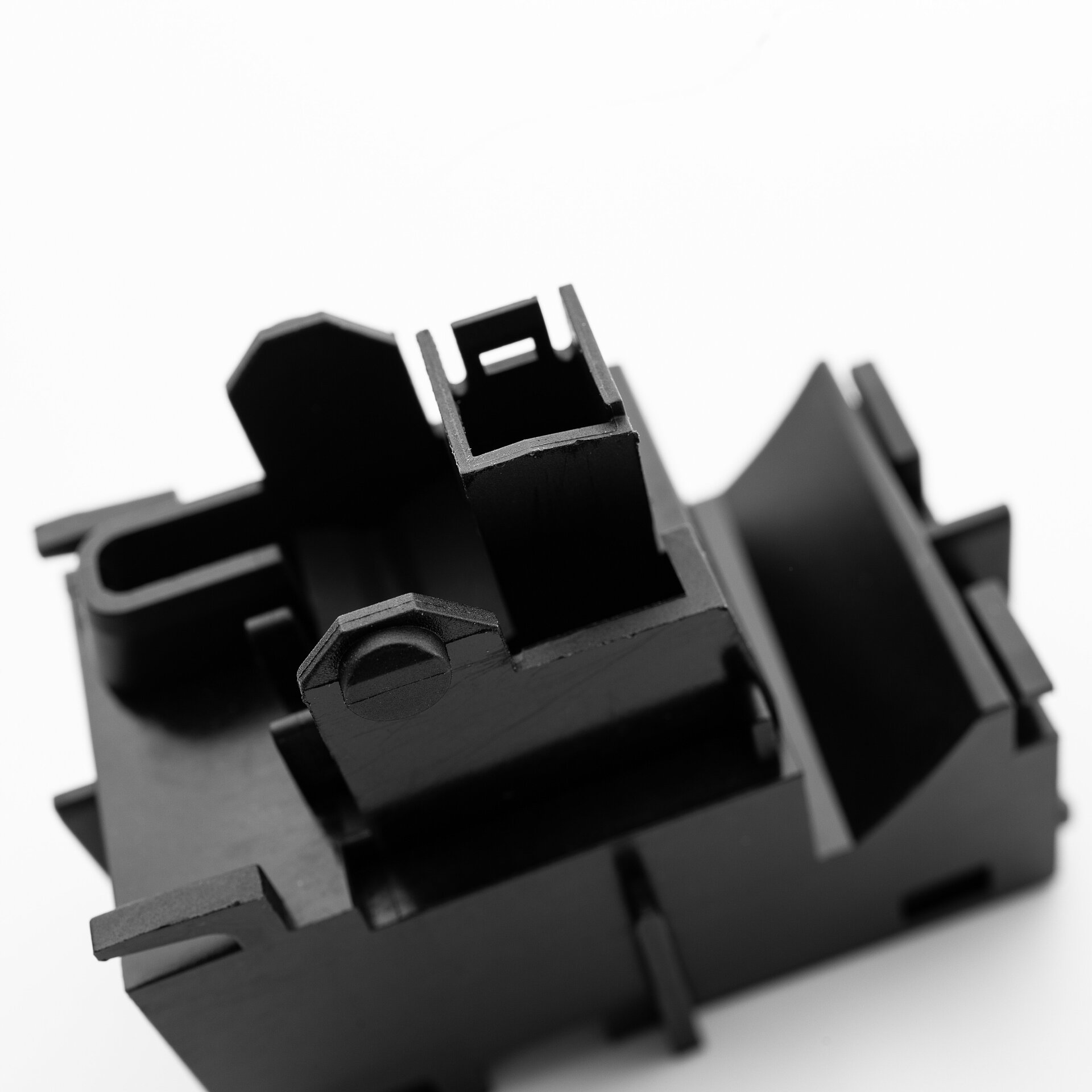

PROTOTYPES

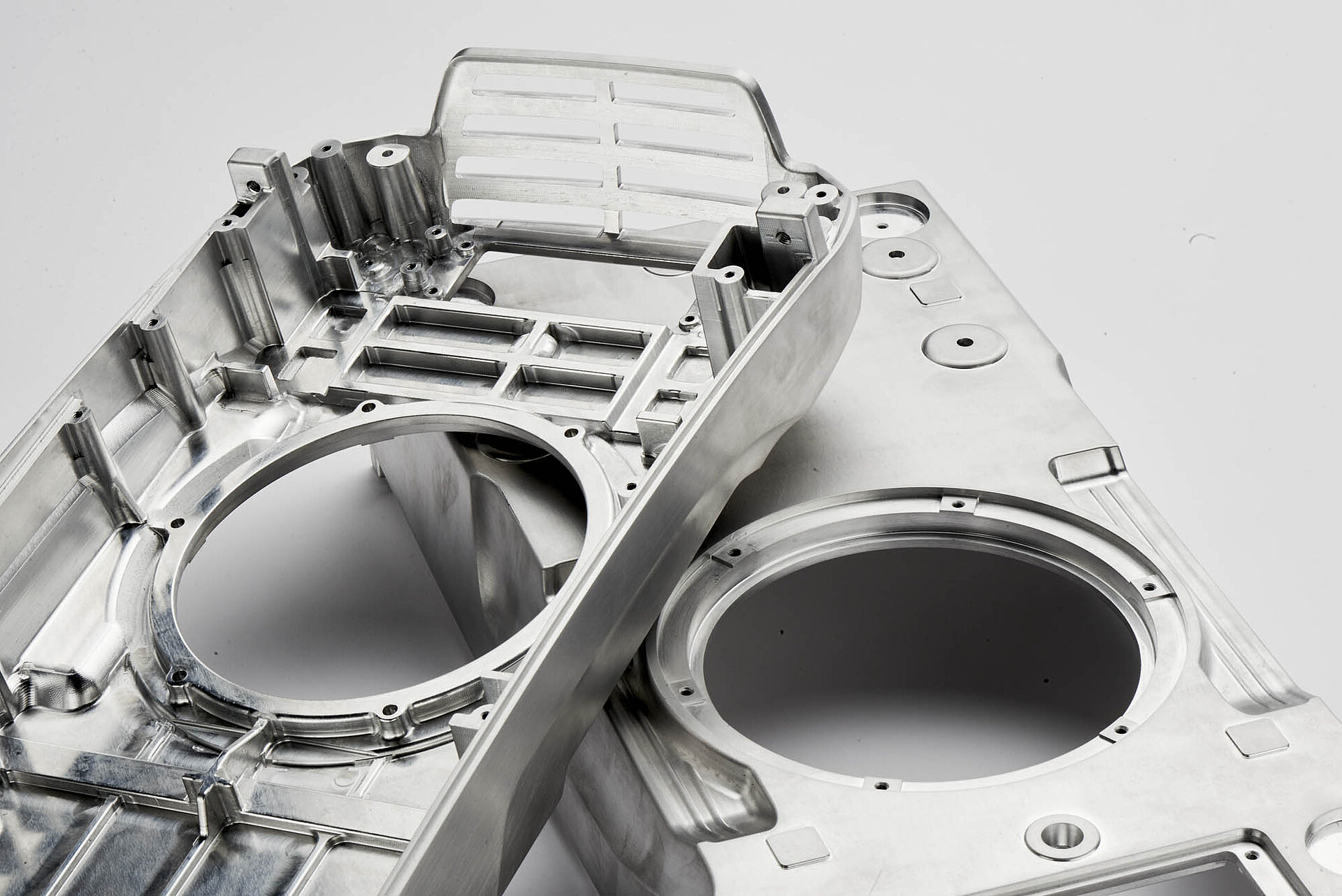

Prototypes for castingsare essential when the function of the product has to be checked prior to series production or during the so-called parallel development. In order to shorten the time-to-market of products, it's all about maximum speed and flexibility.

Kirch facilitates the quick development and production of prototypes for castingswith materials that are, for the most part, the same as those used for series production. In particular, small batch producers of machines, machine components, vehicles or other products will benefit enormously from this. This allows the weekly, monthly or annual production of individual castingson commission. That allows you to prevent high storage costs and losses due to altered versions.

OUR SERVICES IN THE AREA OF

PROTOTYPES FOR CAST PARTS:

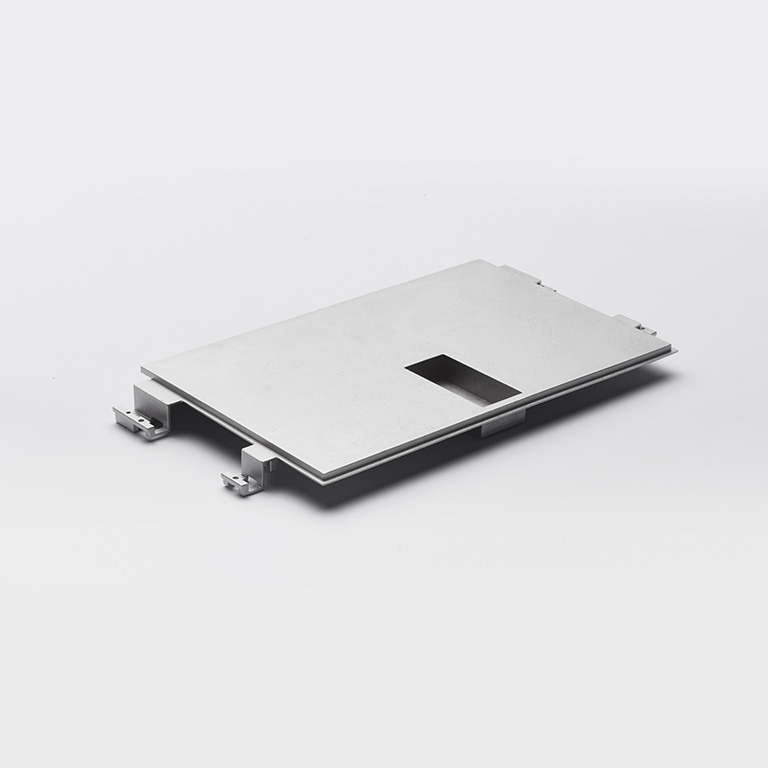

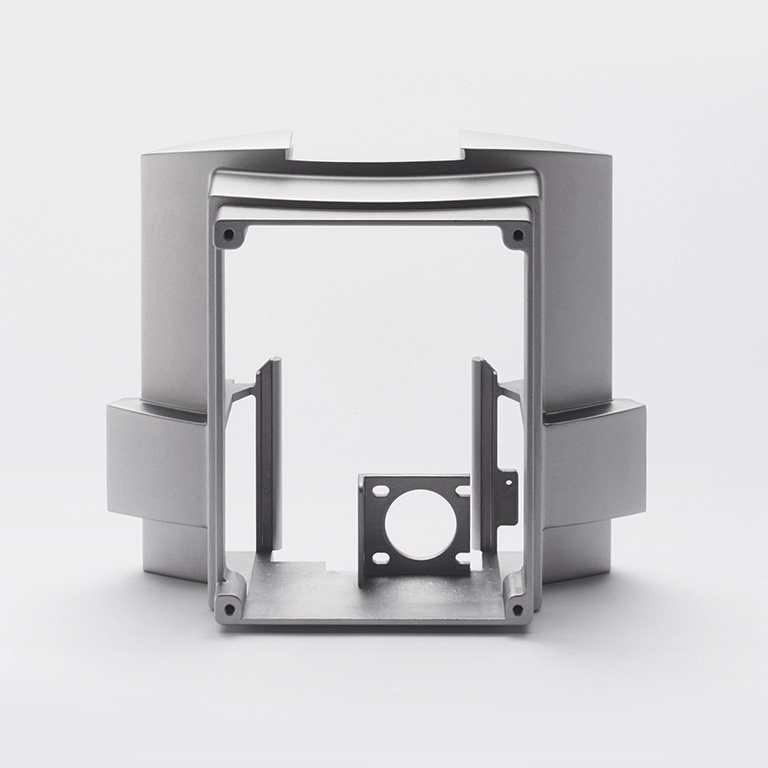

COMPONENTS

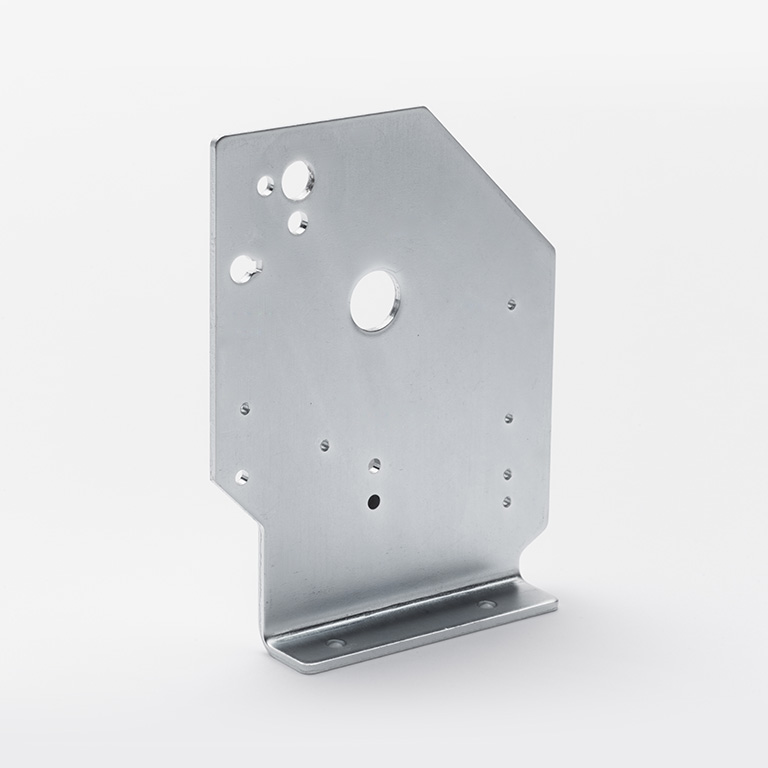

You need high-quality castingsor stamped bending parts, aluminium, brass and stainless steel solid material parts according to your specifications? You are looking for stainless steel connecting elements or screws and nuts as DIN versions or as standard parts? Kirch will develop and produce needs-based components for a wide range of uses and industries. With top quality and in any lot size you want.

OUR SERVICES IN THE AREA OF COMPONENTS:

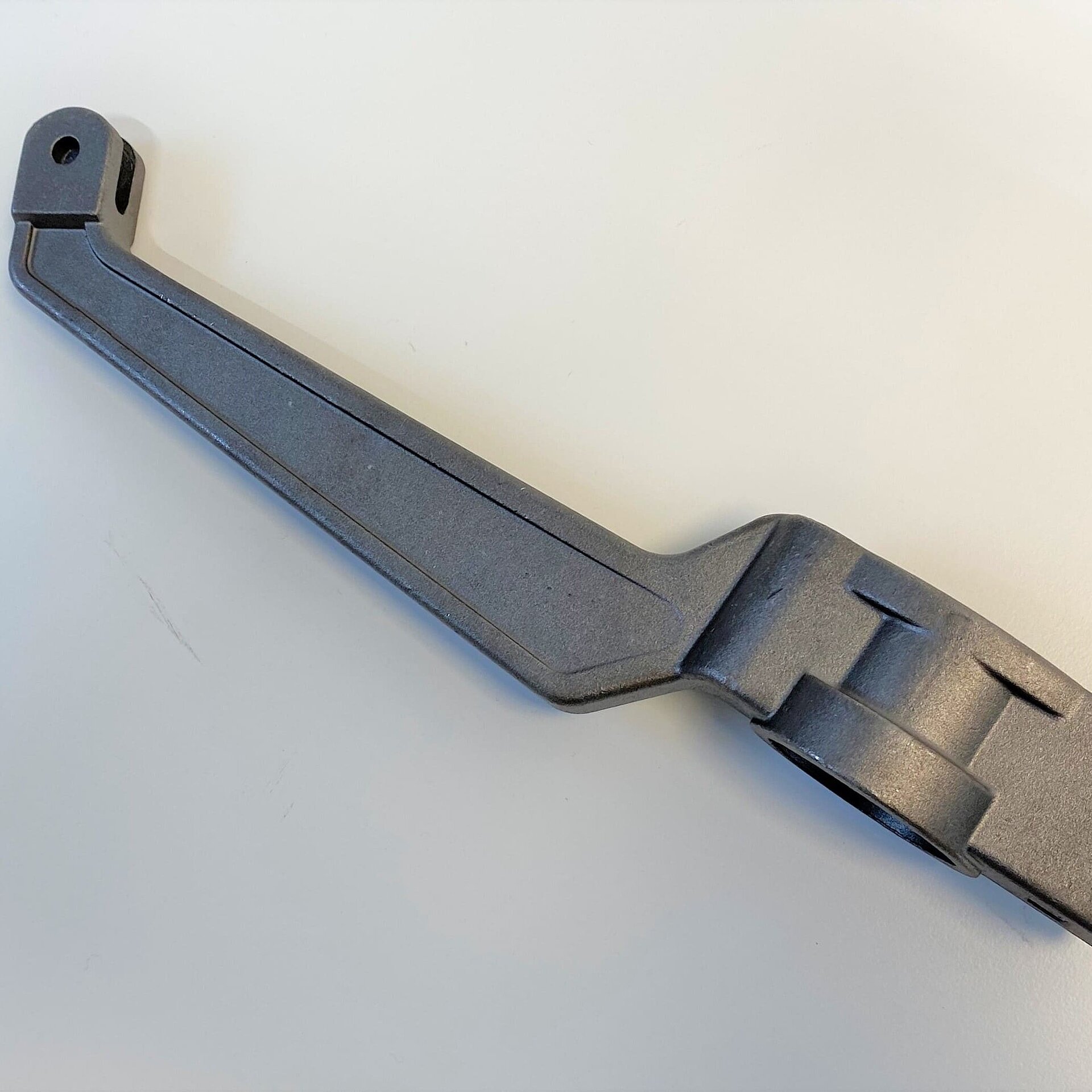

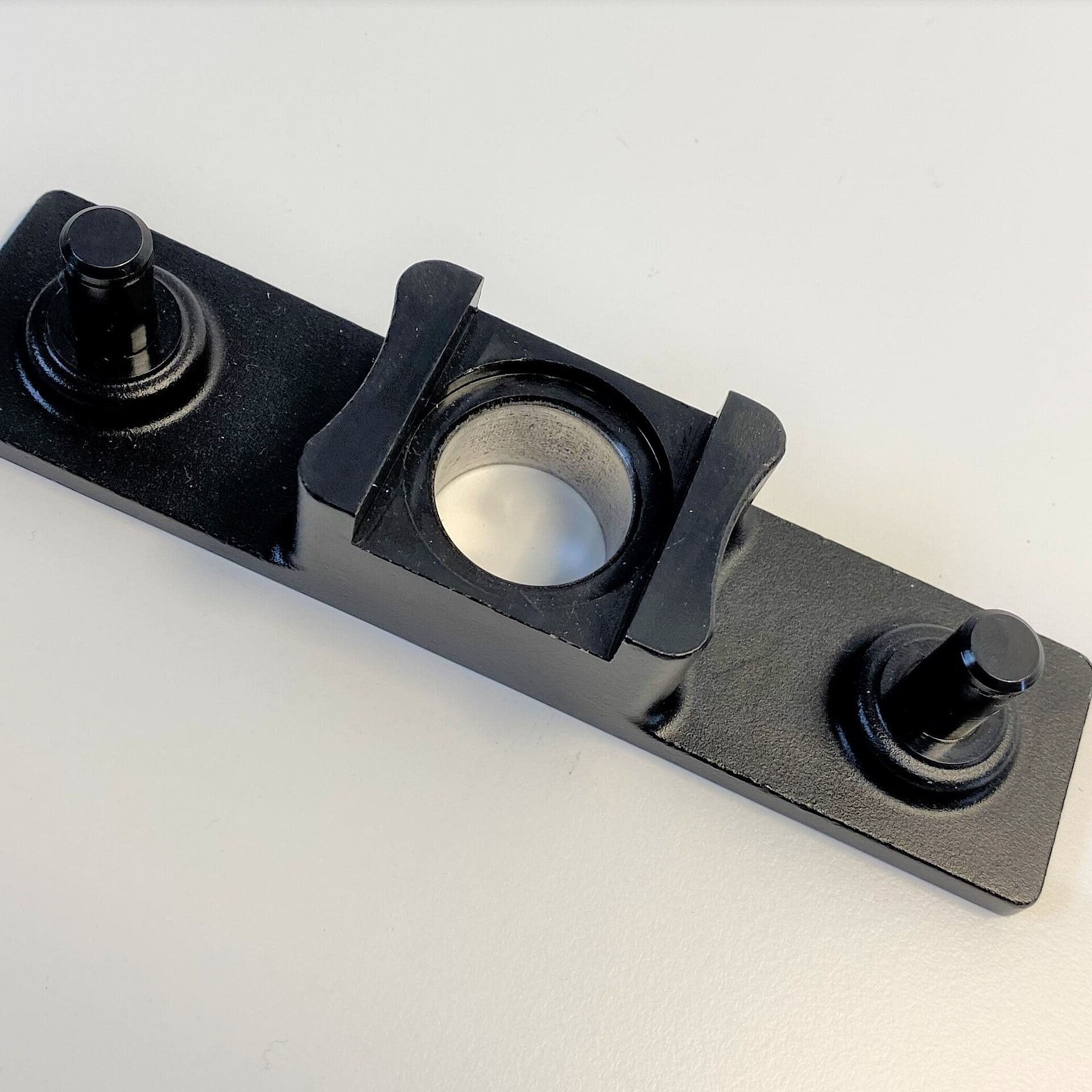

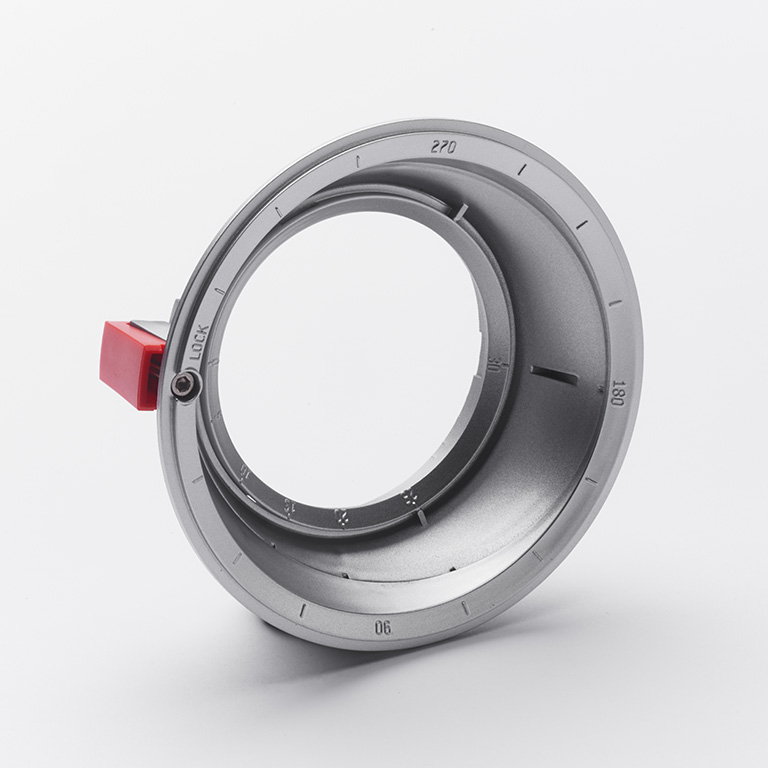

HINGES, CLOSURES, ACCESSORIES

We will develop rolled or milled high-quality hinges, closures and accessories for a wide range of uses. We can produce standard or customer-specific versions of all hinges, closures and accessories for you. It's up to you.

HERE IS WHAT OUR HINGES,

CLOSURES AND ACCESSORIES HAVE TO OFFER:

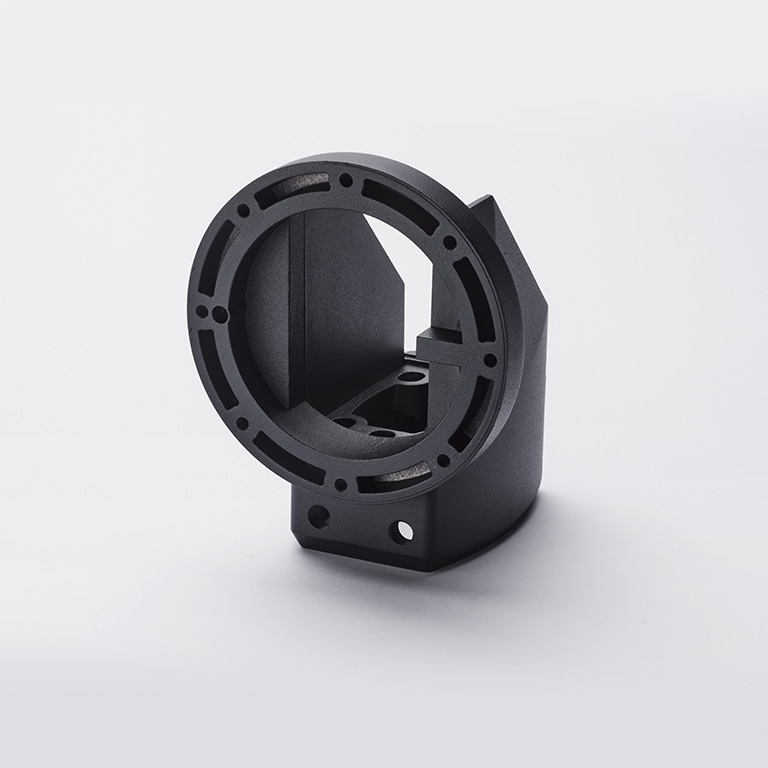

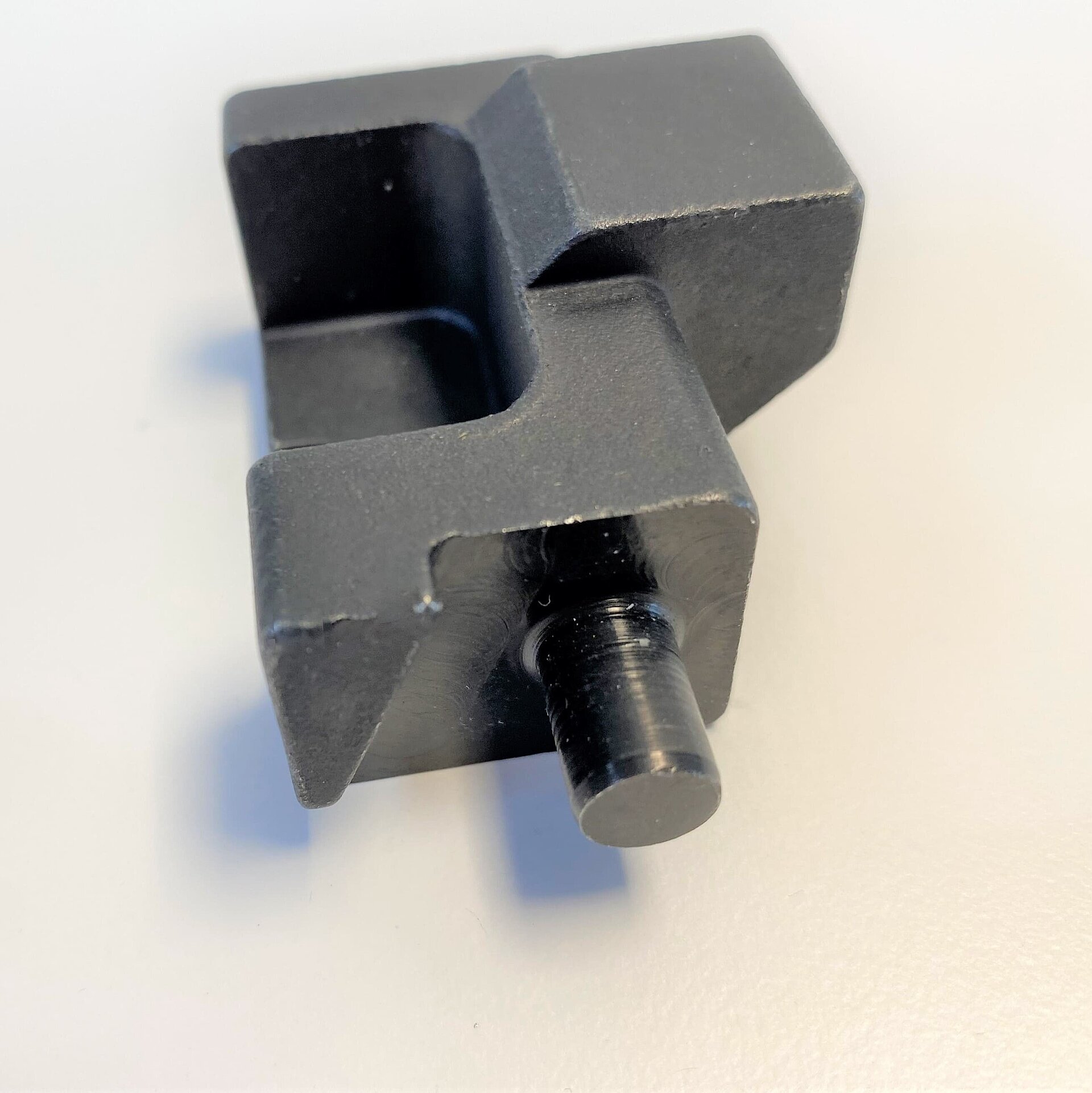

METAL INJECTION MOLDING (MIM)

It is much more difficult to process metal and ceramics than plastics using traditional production processes such as machining or casting. Metal injection molding, however, makes it possible to combine the simple shaping process of injection molding with the material properties of metal and ceramics. This pays off, especially in the case of components with complex geometries. The products are also very reproducible, even in high quantities – at low unit costs.

HOW YOU BENEFIT FROM METAL INJECTION MOLDING:

- Tailor-made products with a variety of finishes

- Ideal for complex components thanks to narrow tolerances

- Outstanding reproducibility for all batch sizes

- Ready-to-install components with low unit costs

- Highly efficient and resource saving through material recovery of almost 100%

- Environmentally friendly due to recyclable components

- Lighter weight compared to components produced with other processes

EX STOCK ROTTWEIL

We can warehouse and deliver your products directly from our company headquarters in Rottweil upon request. This also allows you quick access to your products while reducing your warehousing and employee capacities and lowering logistics costs.

Our internal warehouse currently has 500 pallet bays. We also have access to an additional 1,000 external pallet bays. So we can store and supply even large quantities without any problem. Incoming and outgoing goods are monitored by cameras that, thanks to automated, computerized image documentation, provide maximum security as well as traceability of the products.

A service that literally pays off for you!

CONTACT WITH KIRCH.

ALWAYS WELL TAKEN CARE OF.

You want to benefit from Kirch's comprehensive development and production know-how and find out more about the services we offer? Or do you have a specific project in the areas of cast parts, plastic parts, aluminium profiles and prototypes? We will be happy to advise you. Competently and in person. It just takes a phone call or an email!

Paul-W. Kirch

Management

Tel: +49 741 174124-0

Fax: +49 741 174124-29

paul.kirch@kirch-engineering.com