UNCOMPROMISING TOP QUALITY – FOR TOP PRODUCTS TO YOUR SPECIFICATIONS

When developing and producing high-grade cast parts, plastic parts, aluminium profiles, prototypes, MIM parts and components, top quality always comes first – especially when it comes to complex projects. That’s what sets us apart. And that is what our customers appreciate. Here’s how we do it!

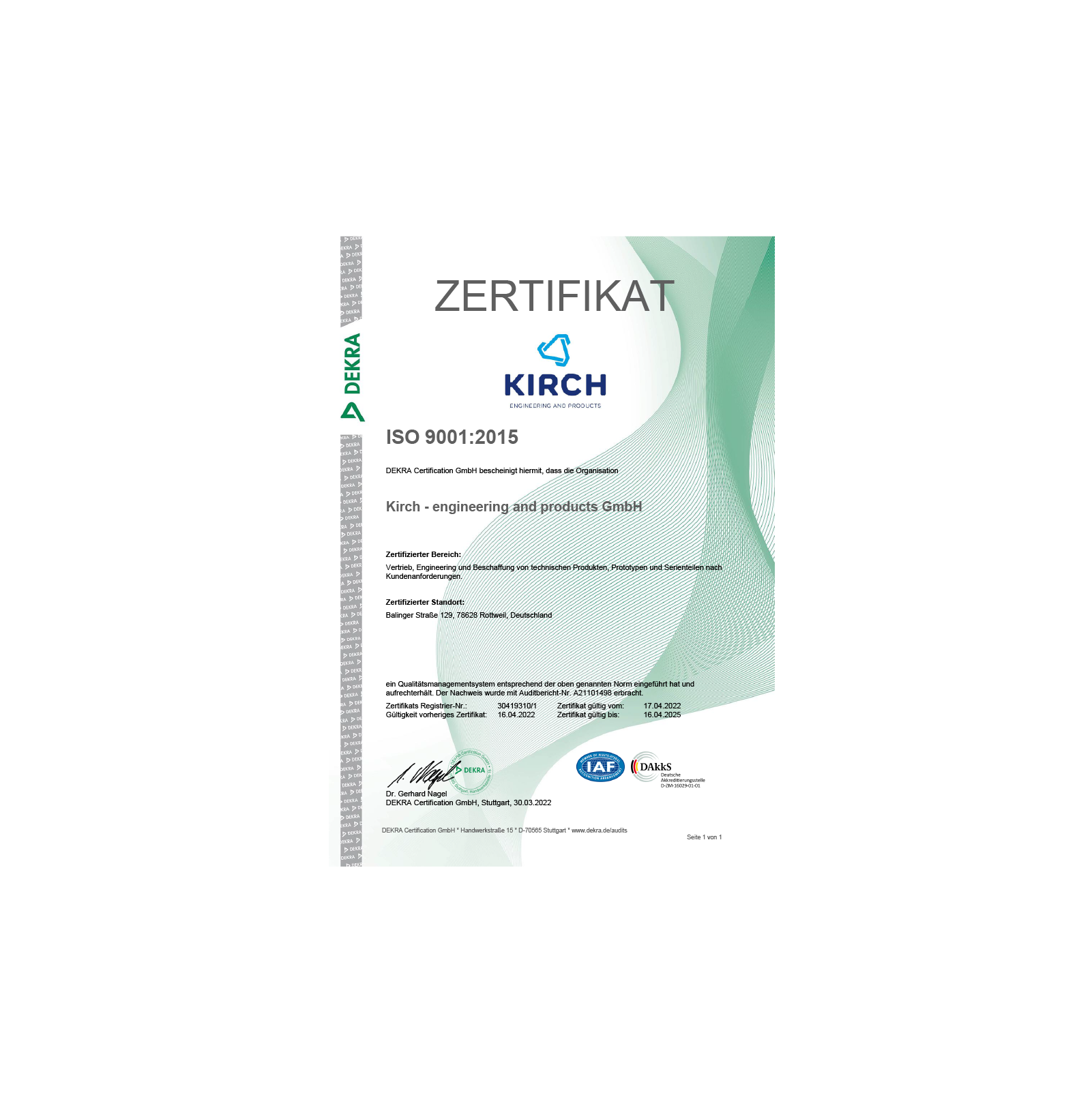

Certified quality management

Our quality management has been certified in accordance with DIN ISO 9001 since April 2019. Whether your product developments are simple or complex, you can always rely on comprehensive quality assurance and top product quality. No matter if high-quality prototypes, small batches or large-scale production. You have our word!

Highly precise 3D measurement

Our image-guided Keyence XM coordinate measuring machine is an investment that really pays off. This cutting-edge 3D measuring system can measure the shape of all product samples to a precision of 7μ. These measurements make it simple to create reliable, compliant initial sample test reports in house

What's in it for you? You can always rely on product quality that is exactly what you want as well as fully documented and traceable.

CONTACT WITH KIRCH.

ALWAYS WELL TAKEN CARE OF.

You want to benefit from Kirch's comprehensive development and production know-how and find out more about the services we offer? Or do you have a specific project in the areas of cast parts, plastic parts, aluminium profiles and prototypes? We will be happy to advise you. Competently and in person. It just takes a phone call or an email!

Paul-W. Kirch

Management

Tel: +49 741 174124-0

Fax: +49 741 174124-29

paul.kirch@kirch-engineering.com