CNC prototypes, samples & single parts for individual requirements

Almost serial, turned or milled prototypes and individual parts are indispensable in product development at every stage of development. In prototyping and sample construction, for example, the most demanding customer requirements must be implemented in the shortest possible time from plastic or metal to meet the high demands of series production. Here you can rely entirely on the development competence and many years of experience of Kirch engineering and products in the field of CNC turned parts, CNC milled parts and CNC prototypes. We accompany you throughout the entire project, from consultation to series release. And we transform your ideas not only into a physical component, but into a high-quality product.

CNC turning & CNC milling for prototypes, single parts & samples according to demand

Depending on the application, CNC lathes, CNC milling machines or CNC turning/milling centers are used for your components:

- CNC turning: CNC turned parts are produced on CNC lathes by a rotary motion of the workpiece combined with translational motions of the tools. Thanks to the high material removal rate, CNC turning is extremely cost-efficient.

- CNC milling: CNC milled parts are machined on CNC milling machines using rotating tools. 3-axis, 4-axis and 5-axis milling machines are used.

- CNC turning & milling: Combined turning/milling centers enable complete machining of workpieces from several sides in one clamping.

For the CNC production of your components, you can choose from a wide range of materials made of plastic and metal. Precise CNC machining of your components, e.g. rapid tooling and rapid prototyping, enables them to meet even the tightest tolerances.

To ensure that you don't have to worry about anything and that we can guarantee the highest quality of your turned or milled prototypes, samples and individual parts, we also take care of downstream assembly and processing steps, such as surface finishing.

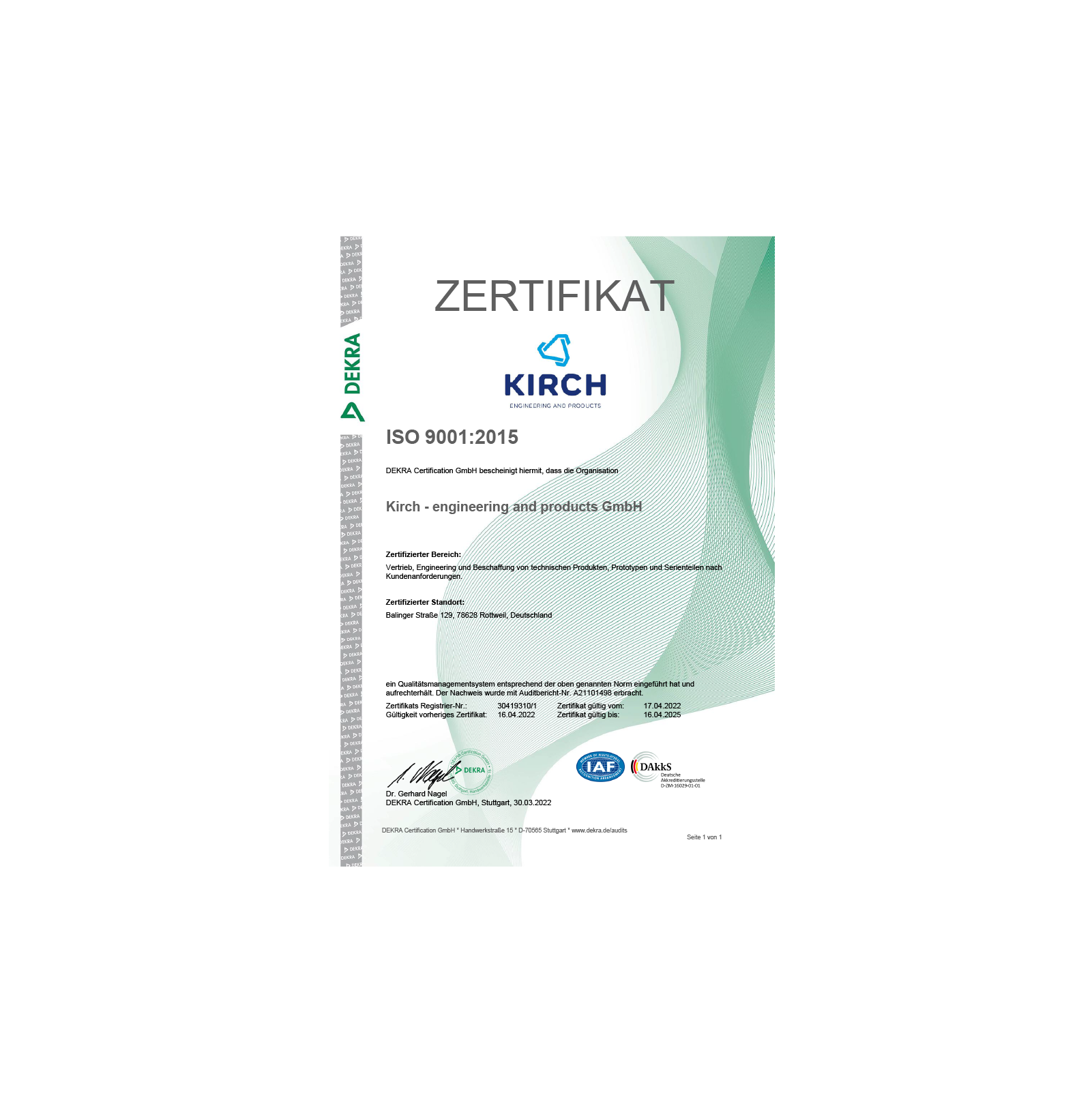

Certified quality management

Our quality management has been certified in accordance with DIN ISO 9001 since April 2019. Whether your product developments are simple or complex, you can always rely on comprehensive quality assurance and top product quality. No matter if high-quality prototypes, small batches or large-scale production. You have our word!

CONTACT WITH KIRCH.

ALWAYS WELL TAKEN CARE OF.

You want to benefit from Kirch's comprehensive development and production know-how and find out more about the services we offer? Or do you have a specific project in the areas of cast parts, plastic parts, aluminium profiles and prototypes? We will be happy to advise you. Competently and in person. It just takes a phone call or an email!

Paul-W. Kirch

Management

Tel: +49 741 174124-0

Fax: +49 741 174124-29

paul.kirch@kirch-engineering.com