Low cost injection moulds & prototypes in plastic & metal

With injection moulding prototype tools made of plastic or metal for toolmaking and mould construction, it is important that they fully meet the requirements of series production. Here you can rely entirely on the development expertise and many years of experience of Kirch engineering and products in the field of rapid tooling or injection moulding prototype tools. Through "rapid tooling" (rapid tooling or also additive manufacturing), high-quality injection moulding tools can be produced cost-effectively to your specifications in just a few days.

Injection moulding prototypes for pilot series & small batches

Our special expertise lies in the development and production of pilot series and small series for injection moulding prototypes made of plastic and metal. We accompany you throughout the entire project, from consultation to series release.

Rapid tooling with efficient technologies

For your individual injection moulding prototype tools, we process all conventional thermoplastics and elastomers as well as high-temperature materials. 2-component prototypes (e.g. combination of a hard and soft component) are also possible without any problems. In the metal sector, aluminium and steel are used for your prototype injection moulding tools with shape tolerances and surface qualities that meet your requirements.

So that you don't have to worry about anything and so that we can guarantee the highest quality of your injection moulding tools, we also take over downstream assembly and processing steps, such as surface finishing.

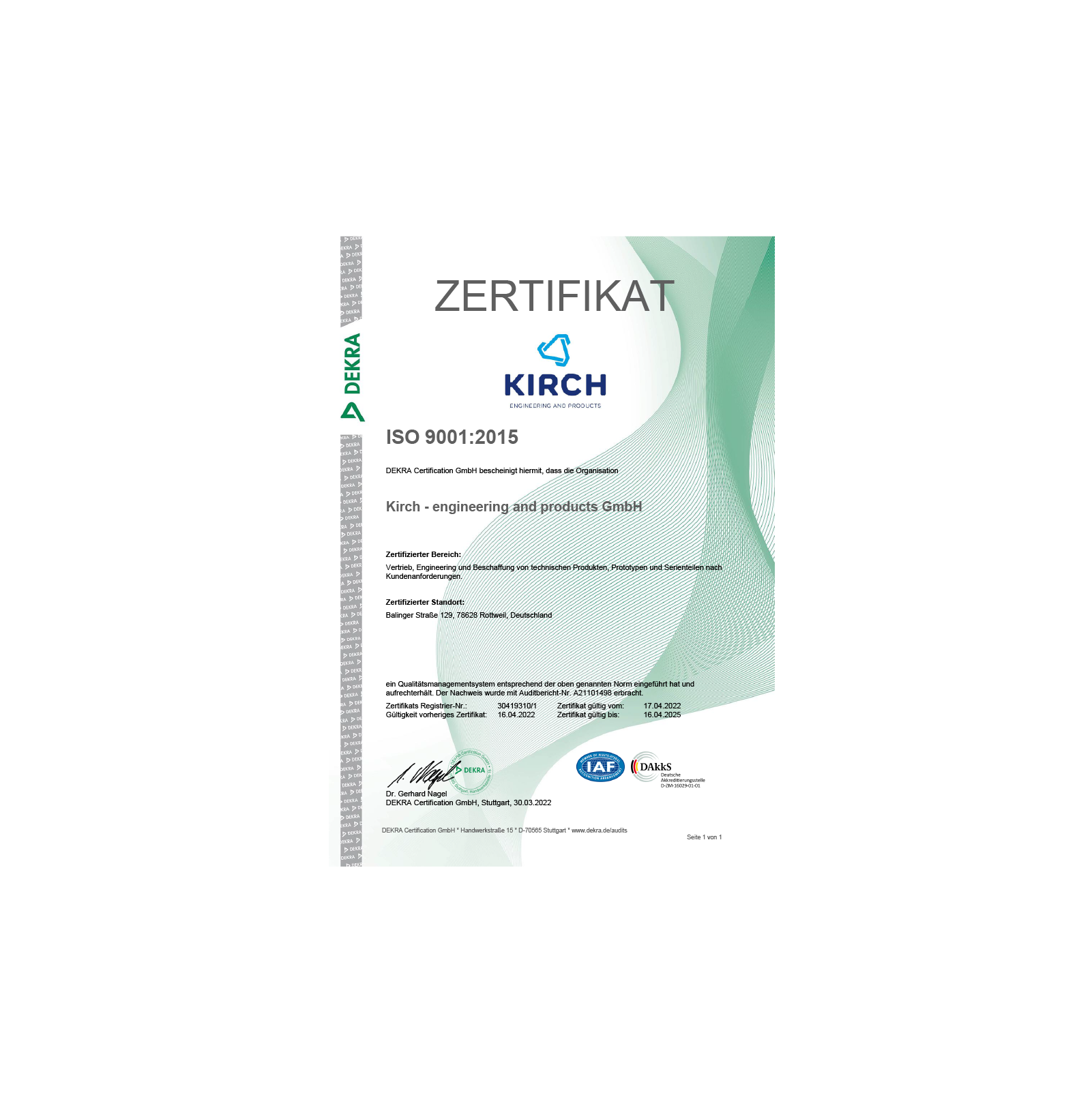

Certified quality management

Our quality management has been certified in accordance with DIN ISO 9001 since April 2019. Whether your product developments are simple or complex, you can always rely on comprehensive quality assurance and top product quality. No matter if high-quality prototypes, small batches or large-scale production. You have our word!

CONTACT WITH KIRCH.

ALWAYS WELL TAKEN CARE OF.

You want to benefit from Kirch's comprehensive development and production know-how and find out more about the services we offer? Or do you have a specific project in the areas of cast parts, plastic parts, aluminium profiles and prototypes? We will be happy to advise you. Competently and in person. It just takes a phone call or an email!

Paul-W. Kirch

Management

Tel: +49 741 174124-0

Fax: +49 741 174124-29

paul.kirch@kirch-engineering.com